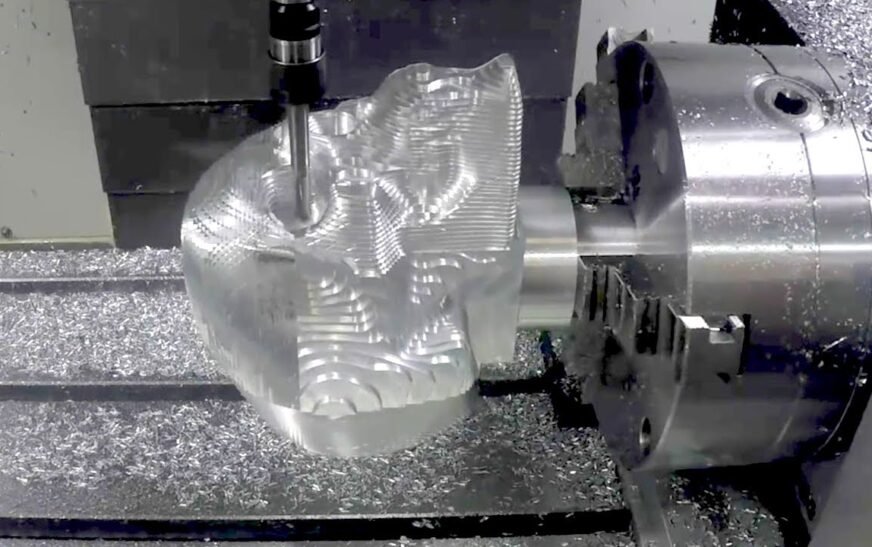

Have you ever wondered how CNC machines manufacture such complex, advanced components? A 5 axis CNC machine plays a big part in making these parts for various industries. It’s different from older 3 axis machines because it has two extra arms that spin and turn tools in even more directions. This allows them to work on all sides of a piece of material at once.

Operating a 5 axis CNC takes practice, but with the right training you’ll be able to manufacture almost any design. It allows for infinite possibilities in part sizes and shapes through subtractive machining on five programmable axes, delivering high precision and accuracy.

In this article, we will explain step-by-step how to operate a 5 axis CNC machine, including its setup, tooling, programming, and running.

What is a 5 Axis CNC Machine?

A 5-axis CNC machine has capabilities that go beyond a simple 3 axis CNC machine. It can move tools in five different directions, rather than just three. This allows it to create extremely complex shapes and sculpture-like forms.

A 5 axis CNC operation involves three linear axes, like a 3 axis CNC, which are the X, Y, and Z axes. These move the material left/right, forward/back, and up/down.

In addition, it has two rotary axes that allow tools to spin and tilt in different positions. They are usually some combination of the A, B, and C axes, whereas.

- The A axis allows rotation around the X axis. This lets the tool spin from side to side.

- The B axis allows rotation around the Y axis. It can tilt the tool forward and back.

- The C axis makes the tool or material spin like a record, rotating around the Z axis.

With all five axes, a 5-axis machine gives tools six directions of movement—three linear and three rotational. This makes it possible to work on all sides of a part at once.

Compared to 3-axis machines, 5-axis CNCs offer more flexibility and the ability to produce more intricate geometries. They are well-suited for mold making, aerospace parts, and anything with complex curves or multi-sided features.

The tradeoff is that 5-axis machines require more advanced programming and have a steeper learning curve. But for jobs requiring it, they provide unbeatable machining capability.

How to Operate a 5 Axis CNC Machine Step-by-Step

It takes patience and practice for 5 axis CNC operation. So, after going through this guide, don’t forget to invest your time on training to master how to use the machine correctly.

The steps to operate a 5 axis CNC are:

a. Setting up the Machine

The first step is preparing the workpiece to be machined. Mount the workpiece holder, which could be a hydraulic clamp, zero clamp vice, or a block, securely in the center of the machine table. The workpiece should be accessible from all sides by the cutting tools.

Setting up the cutting tools is your next task. Measure and prepare each tool, then load them into the machine’s tool changer, which holds all the tools the machine will need.

You must not forget to calibrate the machine before production starts. Calibration makes sure all the axes move correctly. The machine uses a special probe and software to make sure about the correct calibration. The whole process may take from one to a couple of minutes. Since accuracy is key for 5-axis machining, you should do the calibration before starting every batch of production.

Doing all these things make the machine ready for programming and production. The next step of operation is programming the machine correctly.

b. Programming the Machine

Programming is an integral part of how to operate a 5 axis CNC machine. You need it for drilling, tapping, and milling components. It will tell the machine what motions to make with its axes and what tools to use. For simple shapes, you can program right on the machine control panel with the help of special macros and subroutine programs.

But for more complex jobs, it’s best to use CAD/CAM software. These programs let you design the part on the computer first. Then, you can add tools and choose the machine motions.

5 Axis CNC Programming Steps at a Glance

| Programming Step | Description |

| Designing in CAD | Use CAD software like SolidWorks or Inventor to design the 3D part model. Add measurements, holes, engraving details. |

| Creating Toolpath in CAM | In the CAM software, select tools, simulate their motion through the design. CAM automatically generates optimized toolpaths and calculates speeds/feeds. |

| Loading the G-Code | The CAM generates the G-code, which is the numeric language the CNC understands. It precisely describes all tool motions and axis positioning to machine the part. |

Let’s find out more about the CAD and CAM software and the CNC process they initiate:

i. Designing in Computer-Aided Design (CAD)

To program your 5-axis CNC machine, the first step is to design the part on the computer. And for designing, you need a CAD program, like SolidWorks or Autodesk Inventor, that allows you to draw the shape you want in a 3D format.

It’s helpful to design your part digitally before cutting it out. In the CAD program, you build the model by adding different lines and shapes together. You can also add measurements, holes, or engraving details to the design

CAD software lets you design and test shapes virtually before taking it to production. It’s a key part of programming any CNC efficiently, including complex 5-axis machines.

ii. Creating Toolpath in Computer-Aided Manufacturing (CAM)

After designing in CAD, the next step is to create a machining plan in CAM software so your 5-axis CNC knows what to do.

In the software, you pick tools like mills or drills that will cut the shape. Then you simulate how the tool will move through your part design. For example, you can route a trail for an end mill or pick spot locations for drill holes. The software makes sure the tools won’t crash into the material.

Next, CAM automatically works out the best paths for the axes and tools. It calculates speeds and feeds to cut accurately and safely. You can edit the plan if needed. But CAM does the heavy lifting of sequencing the machining process.

When the CAM program is done, you export it as G-code instructions. This is a numeric language that CNC machines understand. The post processor in CAM changes the plan into codes specific for your 5-axis machine model.

iii. Loading the G-Code

After you finish designing the part in CAD and creating a toolpath in CAM, the next step of operating a 5 axis CNC is interpreting the G-code. This is how a CNC machine knows what to do.

G-code is a special programming language that CNCs understand. It uses letter and number codes to describe tool motions. For example, a G00 code tells the tools to move quickly between cutting positions while a G01 code makes the tool cut at a programmed speed and depth.

The code lists out every small movement needed to machine the full part shape. Lines of code position the axes and call tools for various cutting motions. Better CAM programs write cleaner G-codes, which are easier for machinists to read.

Loading the G-code into a 5-axis CNC is the final step to make the program run. Understanding this language helps you know the machine will operate correctly to cut parts just as designed on the computer.

c. Testing the Machine

Testing your 5 axis machine is important before using it for real projects. After setting up the machine and programs, you need to check if everything will work right.

Watch the machine’s path when running your program. Make sure the tool or parts won’t bump into anything. Once checked, run the program step-by-step. Move it slowly so you see each line do what it should. Is the tool changing when expected? Are the positions correct for each cut or movement? This lets you find any mistakes before running at real speed.

Mistakes can be expensive. A crash from a wrong program can damage the expensive machine. It may require time and money to repair parts. The machine may even need realignment, which requires professional fixing. Running tests slowly helps ensure things work properly before a costly crash occurs.

Conclusion

Learning all these steps of how to operate a 5 axis CNC machine will allow you to produce almost any complex part design. Practicing the programming and operation will help gain experience to take full advantage of the machine’s advanced capabilities. With precision machining, 5-axis CNCs enable endless possibilities for innovative designs and solutions.

Put your designs to the test using Zintilon’s 5 axis CNC machining services. Our experienced technicians can help program your precision parts for prototyping or production. Contact us to discuss your project needs.