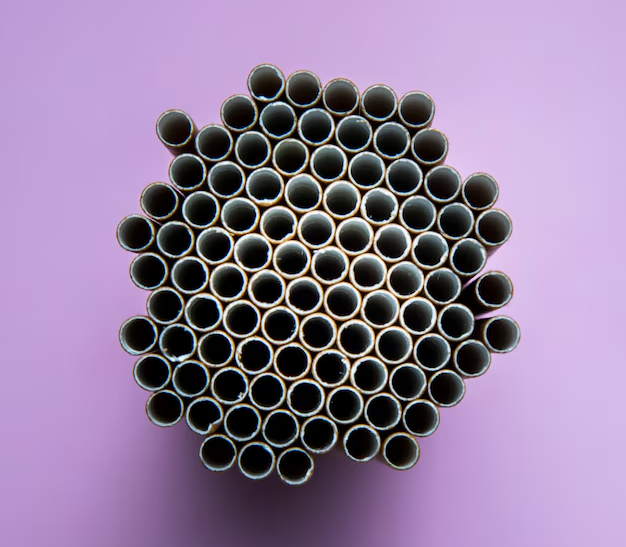

Industrial applications require reliable and durable materials, and CPipe stands out as a top choice. Known for its exceptional properties and versatility, CPipe meets the rigorous demands of various industries. This article explores the key reasons behind CPipe’s suitability for industrial use.

Exceptional Corrosion Resistance

Industries often operate in harsh environments where materials are exposed to corrosive substances. CPipe, especially the c276 pipe variant, offers superior corrosion resistance, making it ideal for such conditions. The c276 pipe’s ability to withstand harsh chemicals ensures longevity and reliability in industrial settings.

Furthermore, the c276 pipe demonstrates remarkable performance in both oxidizing and reducing environments, ensuring it remains intact and functional over extended periods.

Corrosion resistance is critical for maintaining the integrity of pipelines and systems. CPipe’s resilience against corrosion reduces the risk of leaks and failures, which can be costly and dangerous in industrial contexts. This advantage is particularly significant in industries such as chemical processing, oil and gas, and power generation, where exposure to corrosive elements is common.

Additionally, CPipe’s resistance to corrosion extends to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking. These forms of degradation can severely impact the performance and safety of industrial systems. By choosing CPipe, industries can mitigate these risks, ensuring smooth and uninterrupted operations.

High Strength And Durability

Industries demand materials that can withstand high pressures, temperatures, and mechanical stress. CPipe is renowned for its strength and durability, making it a preferred choice for demanding applications. Its robust construction allows it to handle extreme conditions without compromising performance. This high strength ensures that CPipe can support heavy loads and maintain structural integrity, even in challenging environments.

Durability is another critical factor for industrial applications. CPipe’s ability to resist wear and tear extends its service life, reducing the need for frequent replacements. This durability translates to cost savings and enhanced operational efficiency for industries that rely on continuous and reliable performance from their piping systems.

Moreover, CPipe’s mechanical properties remain consistent across a wide range of temperatures. This stability is essential for applications where temperature fluctuations are frequent. Industries can rely on CPipe to maintain its performance and structural integrity, regardless of the operating conditions.

Versatility And Adaptability

- Wide Range of Applications: CPipe’s versatility makes it suitable for a broad spectrum of industrial applications. It can be used in chemical processing plants, power generation facilities, oil and gas refineries, and more. This adaptability ensures that industries can rely on CPipe for various needs.

- Customizable Solutions: CPipe can be customized to meet specific requirements. Whether it’s a particular size, shape, or alloy composition, CPipe manufacturers offer tailored solutions to match the unique demands of different industries. This customization capability enhances CPipe’s utility across diverse applications.

- Compatibility with Other Materials: CPipe is often used alongside other materials in complex industrial systems. Its compatibility with different metals and alloys ensures seamless integration into existing setups, making it a versatile choice for upgrades and expansions.

The ability to tailor CPipe to specific industrial requirements makes it a flexible and valuable option. Whether an industry needs piping for transporting aggressive chemicals or handling high-temperature steam, CPipe can be engineered to meet those needs precisely. This flexibility reduces the need for multiple types of piping, streamlining inventory and maintenance processes.

Cost-Effectiveness

- Reduced Maintenance Costs: CPipe’s resistance to corrosion and durability significantly lowers maintenance costs. Industries can benefit from reduced downtime and fewer repairs, leading to cost savings over the long term.

- Long Service Life: The extended service life of CPipe means fewer replacements and lower lifecycle costs. Investing in CPipe upfront can result in substantial savings compared to using materials with shorter lifespans.

- Energy Efficiency: CPipe’s efficiency in handling high pressures and temperatures contributes to energy savings. Efficient piping systems reduce energy consumption, which is a crucial factor in minimizing operational costs in industrial settings.

Cost-effectiveness is a significant consideration for any industry. The initial investment in high-quality CPipe can lead to long-term savings by reducing the frequency of repairs and replacements. Additionally, the energy efficiency of CPipe systems can lower operational expenses, making it a financially sound choice.

Superior Performance Under Extreme Conditions

- High-Temperature Tolerance: CPipe performs exceptionally well in high-temperature environments. Its ability to maintain structural integrity and performance at elevated temperatures makes it ideal for applications such as power generation and petrochemical processing.

- Pressure Resistance: CPipe’s robust construction allows it to withstand high pressures, ensuring safe and reliable operation in demanding conditions. This pressure resistance is vital for industries where safety and performance are paramount.

- Resistance to Abrasion and Wear: CPipe’s durability extends to its resistance to abrasion and wear. This property is essential for industries that deal with abrasive materials or processes, as it ensures the longevity and reliability of the piping systems.

Handling extreme conditions is often a requirement in industrial applications. CPipe’s ability to withstand high temperatures and pressures makes it suitable for critical applications where failure is not an option. Its resistance to abrasion and wear further enhances its performance in harsh environments, ensuring that it remains operational under the most demanding circumstances.

Conclusion

CPipe’s exceptional properties make it the ideal choice for industrial applications. Its superior corrosion resistance, high strength and durability, versatility, cost-effectiveness, and outstanding performance under extreme conditions set it apart as a reliable and efficient solution. Industries can rely on CPipe to meet their rigorous demands, ensuring safe, efficient, and long-lasting operations. Investing in CPipe translates to reduced maintenance costs, extended service life, and enhanced operational efficiency, making it a smart choice for various industrial applications.